CerMaxTM High Temperature Removable Blankets and Insulation for Engines & Generators

For Exhaust System Components: Mufflers & Silencers, Turbo-Chargers, Flanges & Pipes

· Meets MIL-I-24222, US Coast Guard USCG 164.009, ASTM E84 and UL 2200

For Exhaust System Components: Mufflers & Silencers, Turbo-Chargers, Flanges & Pipes

· Meets MIL-I-24222, US Coast Guard USCG 164.009, ASTM E84 and UL 2200

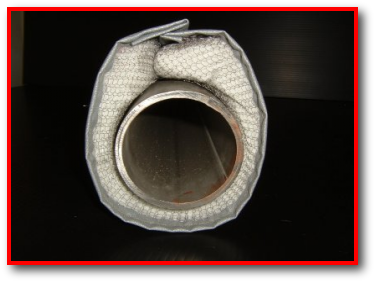

Stainless steel support mesh

Silicone Rubber Coated or Aluminized Fiberglass outer fabric layer

Needled Insulation between outer layer of silicone fabric and inner layer of stainless steel mesh

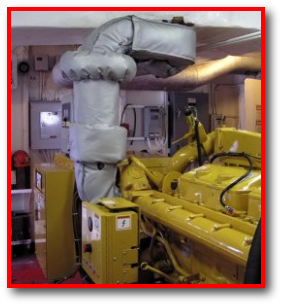

Marine Engine & Generator Removable Blanket Covers for Exhaust System Components: turbo chargers, piping, flanges, flex, silencer-muffler.

Industrial Generator Removable Exhaust Insulation Blankets & Covers

A

B

C

A

B

C

Custom fabricated removable insulation systems for engine and generator exhaust components such as mufflers, turbo-chargers and pipe feature high temperature capability, reduction of thermal radiation and convection within the engine room and sound reduction. Often used for marine powerplants & generators and stationary backup power systems for industrial, commercial and municipal installations.

A thick needled fiberglass or silica insulation is mechanically supported by a stainless steel or inconel mesh and an outer fabric of either silicone rubber coated fiberglass, aluminized fiberglass or silica. Fiberglass is suitable for most non-turbocharged reciprocating engines. Silica may be required for turbo-charged engines and is required for gas turbine engine applications.

A thick needled fiberglass or silica insulation is mechanically supported by a stainless steel or inconel mesh and an outer fabric of either silicone rubber coated fiberglass, aluminized fiberglass or silica. Fiberglass is suitable for most non-turbocharged reciprocating engines. Silica may be required for turbo-charged engines and is required for gas turbine engine applications.

Materials that resist catching fire, burn slowly, or retard burning can be described as either "incombustible", "non-flammable", "non-combustible", "fire-resistant" or "fire-retardant". "Self-extinguishing" materials cease burning once the flame or heat source is removed. "Fireproof" is understood to mean that an object cannot burn, but few materials are truly fireproof.

Most of our products fall within one or more of the above descriptions: they resist high temperature, flame, fire, molten metal splash and weld splatter very well but may melt with prolonged exposures past their designed maximum continuous operating temperature. They can also provide OSHA, ANSI-FM & NFPA compliance and personnel protection.

Using our products to retain heat or cold within pipes, hoses, enclosures or equipment helps conserve energy and resources, and reduces operating costs.

AB Technology Group: Keeping Our World Cooler ä

Most of our products fall within one or more of the above descriptions: they resist high temperature, flame, fire, molten metal splash and weld splatter very well but may melt with prolonged exposures past their designed maximum continuous operating temperature. They can also provide OSHA, ANSI-FM & NFPA compliance and personnel protection.

Using our products to retain heat or cold within pipes, hoses, enclosures or equipment helps conserve energy and resources, and reduces operating costs.

AB Technology Group: Keeping Our World Cooler ä

Removable blanket sections are assembled with either locking wire or spring clips with stainless hook fasteners or mushroom cap rivits mounted on the fabrics.

We maintain drawing sets for most major brands using standard configuration components. For models not on file all we need is a table of dimensions for the components you need covered, or a hand drawn sketch, or if available a CAD drawing or blueprint. A photo of the installation helps if available.

Fabrication time is typically 1 week to 2 weeks after receipt of your order.

Fabrication time is typically 1 week to 2 weeks after receipt of your order.

9/12

The insulation material used meets MIL-I-24244 for low corrosiveness and also meets US Coast Guard 164.009 for incombustible materials.

- Sleeve

- Tape

- Tadpole Tape

- Rope

- Fabric/Cloth

- Insulation

- Sealants & Adhesives